| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : APIE

Model Number : SC Series

Place of Origin : CHINA

MOQ : 1 unit

Price : US$ 400000-550000 Unit

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10 Units per Month

Delivery Time : 30 days

Packaging Details : Nude Packing

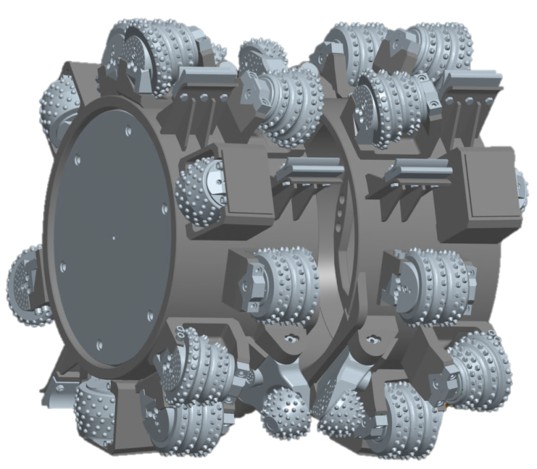

Product name : Trench Cutter

Installed power : 571 kW

Cutters torque : 100 kNm

Maximum depth : 55 m

Max Transport weight : 29.6 m

Height of mainframe : 219/258/260/288/300mm 8''10''12''

Knife Holder Model : SH30/40

Cost Efficiency: Utilizing spherical hobs significantly reduces costs associated with hydromill cutting in hard rock, enabling quicker project completion.

Simplified Operations: There’s no need for precutting holes, which streamlines the required machinery and construction processes.

Extended Operation Time: The hob-tooth hydromill wheel allows for uninterrupted operation for up to 100 hours, minimizing the frequency of hydromill lifts and extending overall project timelines while lowering labor requirements.

Lower Maintenance Requirements: The hydromill module runs efficiently with reduced strain on the gearbox, leading to decreased maintenance time and expenses.

Minimal Environmental Disruption: This technology produces minimal ground disturbance, making it suitable for projects near existing structures.

Enhanced Cutting Deflection: The design improves deflection capabilities during hydromill cutting in difficult rock formations.

High Precision: Trenches can be maintained with vertical alignment accuracy of up to 1‰, ensuring superior quality in results.

Fuel Savings: The system offers over 20% in fuel savings, averaging 73L/h with a CAT C18 engine, promoting energy efficiency and environmental sustainability.

Module Parameter with SC-135

| Parameter | Specification |

| Total hydromill Module Weight | 47–60ton |

| Wall thickness | 1000–2000mm |

| Maximum Torque of Gearbox | 180KNm |

| Gearbox Output Speed | 0–20rpm |

| Maximum Pressing Force | 60 ton |

| Maximum Ground Pressure | 120 ton |

Module Parameters with XCMG 120

| Parameter | Specification |

| Total hydromill Module Weight | 47–60ton |

| Wall thickness | 1000–2000mm |

| Maximum Torque of Gearbox | 180KNm |

| Gearbox Output Speed | 0–20rpm |

| Maximum Pressing Force | 60 ton |

| Maximum Ground Pressure | 120 ton |

|

|

Underground Trench Cutter Machine Diaphragm Wall Trench Cutter Milling Machine Images |